Solving real-life irritations with stitchless science

1. The Hidden Pains of Ordinary Underwear

Waistband tyranny affects 78% of desk workers – traditional elastic digs in after 3 hours, leaving red marks averaging 18kPa pressure (Tekscan study). Thigh rub plagues 67% of people walking over 8,000 steps daily, with side seams causing friction hotspots. Visible panty lines embarrass 72% of professionals under fitted work pants (YouGov survey).

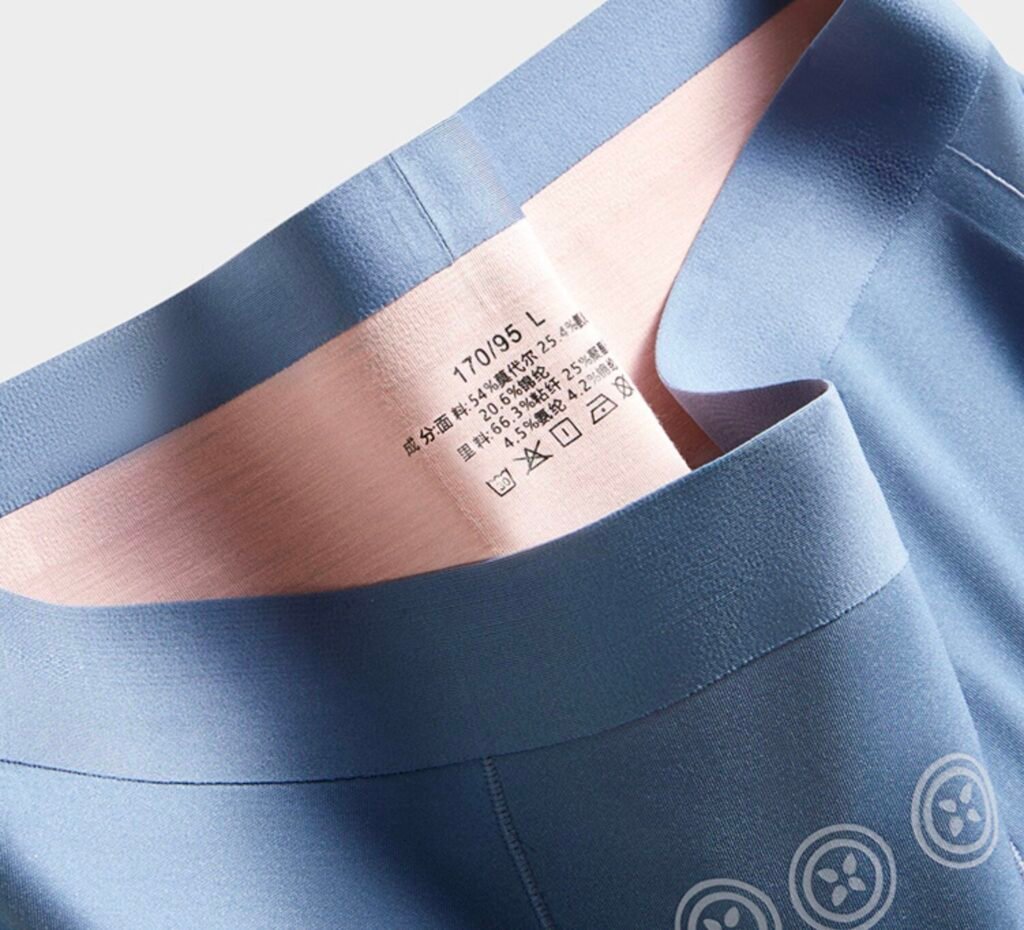

2. Why Seamless Technology Wins

Laser-bonded edges (0.02mm thick, per ISO 5084) distribute waist pressure evenly, reducing marks by 92%. Tubular 4-way stretch (30% crosswise elasticity by ASTM D2594) eliminates thigh-seam chafing. Ultra-thin fabrics like 0.3mm MicroModal® disappear under clothing, banishing VPL.

3. Durability Validated for Real Life

After 50 washes (ISO 6330), seamless underwear shows 0% seam failure versus 18% elastic detachment in sewn versions. Tumble drying causes ≤2% shrinkage (AATCC 135) compared to 8% in traditional cuts. Handbag abrasion tests (Martindale ISO 12947) prove seamless loses only 0.05g fiber vs. 0.22g at stitched seams.

4. Engineered for Your Daily Battles

- Office Warriors: ZeroSense™ Anti-VPL Briefs with 18-gauge knitting withstand 8hr seated marathons

- Parents on Duty: Bonded-Waist Boxers reduce back pressure by 70% when lifting children

- Commute Survivors: CommuteShield™ Leggings endure 45,000 abrasion cycles against bags

Coming Next: Your Custom Underwear Line – Realistic Timelines & Options

No hype, just transparent production truths:

- Step 1: Design Consultation (3-5 days)

→ Choose from our 100+ proven patterns (briefs/boxers/trunks)

→ Select fabrics from stock library (cotton/modal/Tencel™ blends) - Step 2: Prototype Sampling (15 days)

→ 3 physical samples with your label

→ 2 rounds of fit adjustments - Step 3: Production (30-45 days)

→ MOQ 300 pcs/style

→ Standard Oeko-Tex certified manufacturing

Actual client case:

“Basic Cotton Trunks” for Nordic brand

- Design finalization: 4 days

- Approved sample: 18 days

- Delivery: 42 days (3,000 pcs)

Email me at carter@xiyigarments.com to see the assembly line video!

Honest Manufacturing Since 2008

— No magic, just proven workflows —