For decades, the textile industry has perpetuated a simple myth: higher yarn count (e.g., 60s, 80s, 100s) automatically means superior fabric quality. As a garment factory owner in Guangdong with 20 years of sourcing and production experience, I’m here to dismantle this oversimplification. Let’s dive into what yarn count really means, why raw material and process matter more than the number alone, and how to choose wisely for your product.

1. What Is Yarn Count? Demystifying the Numbers

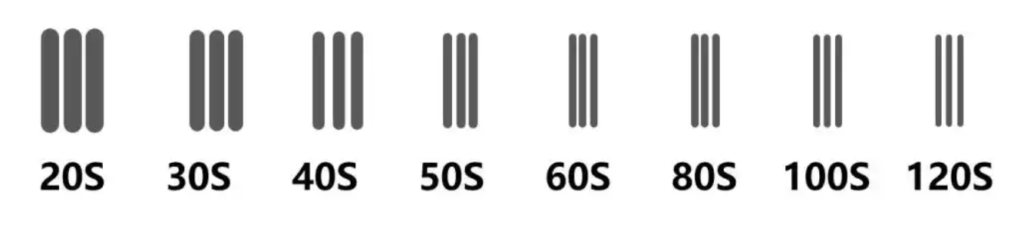

Yarn count measures thread fineness, but its calculation varies by system. For international buyers, three systems dominate:

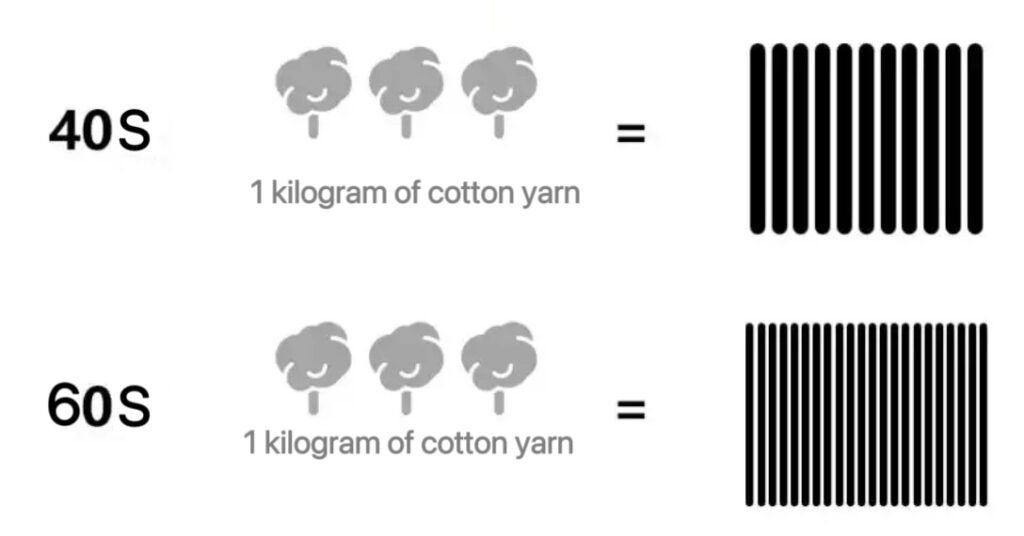

- English Cotton Count (Ne): The most common for cotton. 1 Ne = 840 yards of yarn per pound. Thus, 40s means 1 lb of yarn spans 40 × 840 yards (33,600 yards), while 60s spans 60 × 840 yards (50,400 yards). Higher Ne = finer yarn.

- Metric Count (Nm): Uses kilograms and meters. 1 Nm = 1,000 meters per kg. Common for wool and blends.

- Denier (D): Weight in grams per 9,000 meters of yarn. Used for synthetics (e.g., nylon, polyester). Lower D = finer yarn.

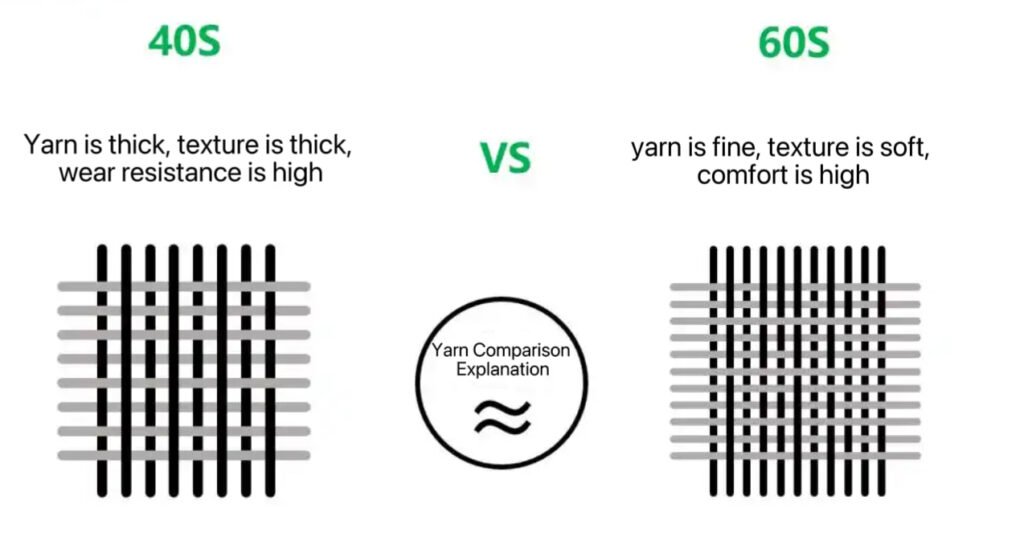

Critical Insight: A 40s yarn isn’t “worse” than 60s—it’s thicker and heavier, making it ideal for durable products like workwear or towels. A 60s yarn is finer, creating softer, lighter fabrics but requiring higher-quality cotton and advanced spinning tech.

2. Beyond the Number: How Raw Material & Process Transform the Same Yarn Count

Two 40s yarns can perform wildly differently based on material and processing:

- Combed vs. Carded Cotton:

- Combed cotton removes short fibers and impurities, yielding smoother, stronger yarns. A 40s combed cotton rivals lower-grade 60s in softness.

- Carded cotton retains shorter fibers, creating slightly napped, breathable fabrics—perfect for rustic towels or casual shirts.

- Fiber Origin & Blends:

- Long-staple cotton (e.g., Egyptian, Pima) spins finer, stronger yarns. A 60s made with short-staple cotton pills easily.

- Polyester-cotton blends (e.g., 70/30) boost durability and reduce cost. We use 40s blends for work gloves needing abrasion resistance.

- Spinning Technology:

Ring-spun yarns (twisted tighter) are smoother than open-end yarns. A 40s ring-spun can outperform a rushed 60s open-end spin.

3. Matching Yarn Count to Product Needs: A Practical Guide

Choose based on function, not prestige. Here’s how we advise clients:

| Yarn Count | Best For | Pros | Cons |

|---|---|---|---|

| 20s–30s | Heavy denim, canvas, upholstery | Extremely durable, cost-effective | Coarse feel, limited softness |

| 40s | Bed linens, shirts, work gloves | Balanced softness & durability; affordable | Less refined than higher counts |

| 60s | Premium shirts, lingerie, luxury bedding | Silky hand feel, lightweight | Requires high-quality cotton; prone to tearing if poorly constructed |

| 80s+ | High-fashion apparel, heirloom linens | Ultra-luxurious drape, breathable | Very delicate; high cost |

💡 Real Case: A client insisted on 80s cotton for hotel bedsheets. Result? Frequent tearing under industrial washing. We switched to a long-staple 60s combed cotton—softness remained, durability soared, costs dropped 30%.

4. Why “Higher = Better” Is a Dangerous Myth

- Durability Trade-off: Finer yarns (60s+) thin faster under friction. For activewear or kids’ clothing, 40s lasts longer.

- Cost Inflation: 60s requires ≈50% more cotton than 40s for the same coverage. If raw material quality dips, you pay premium prices for inferior fabric.

- Weaving Complexity: High-count fabrics (e.g., 80s) demand ultra-fine looms. A slight tension error causes defects. Not all factories can manage this.

5. Smart Sourcing: Key Questions to Ask Your Yarn Supplier

To avoid quality traps, probe deeper:

- “Is this combed or carded? What staple length?” (Long-staple + combed = premium result even at 40s).

- “What’s the twist level?” (Higher twist = stronger yarn).

- “Any fiber blends?” (Polyester boosts strength; elastane adds stretch).

- “Can I see yarn evenness test reports?” (Inconsistencies cause pilling).

The Bottom Line: Context Is King

Yarn count is one metric—not a quality verdict. A well-made 40s from Egyptian combed cotton outperforms a rushed 60s from short-staple cotton. As a factory, we optimize for your product’s purpose: durability, luxury, cost, or comfort. Stop chasing numbers; start understanding material synergy.

Coming Next: Beyond “100% Cotton” – Why Smart Blends Outperform Pure Fibers

Think “100% Cotton” is always the premium choice? It’s time to rethink fabric dogma. In our next blog, we’ll decode:

- The “Pure” Illusion: How international standards (like FTC/ISO) allow “Cotton” labels even with 5-10% synthetics – and why this benefits functionality.

- Blend Superpowers: How 2% Spandex transforms T-shirts, why 30% Polyester boosts workwear longevity, and when recycled cotton needs a nylon backbone.

- Cost vs. Performance: Case studies showing how strategic blends achieve luxury handfeel withoutEgyptian cotton price tags.

Engineer better products: [Subscribe for insights] or bookmark this page. We’ll give you the factory playbook to match fibers to function – no purity guilt attached.

Struggling with fabric choices? Ask below! As a textile engineer and factory owner, I’ll share blend ratios we use for real client projects.